perkenalan produk

Kita mesin pemotong laser serat collocates dengan generator laser canggih yang memancarkan sinar laser dengan kepadatan energi tinggi. Sinar laser difokuskan pada permukaan benda kerja sebagai facula fokus ultrafine dan menyebabkan area yang disinari langsung meleleh dan menguap. Secara otomatis mengontrol pemotong laser untuk mencapai misi pemotongan. Peralatan laser didasari dengan teknologi laser canggih, teknologi CNC dan teknologi mekanik. Ini berlaku untuk memproses lembaran logam seperti baja tahan karat, baja karbon, tembaga, aluminium dan pipa logam. Ini telah banyak digunakan dalam pemrosesan pelat, pembuatan mesin, dan pemrosesan presisi, dll.

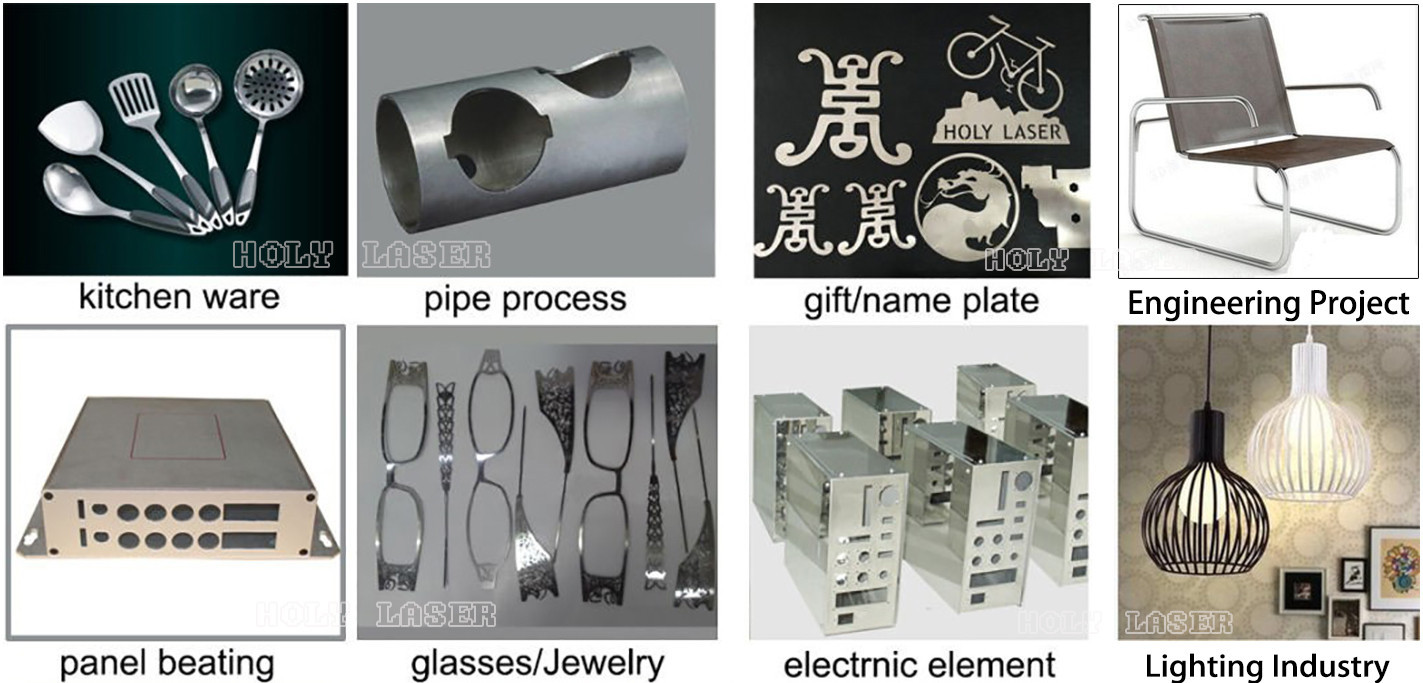

Industri Terapan

Kita mesin pemotong laser logam diterapkan dalam pengolahan lembaran logam, penerbangan, spaceflight, elektronik, peralatan listrik, bagian kereta bawah tanah, mobil, mesin, komponen presisi, kapal, peralatan metalurgi, lift, peralatan rumah tangga, hadiah dan kerajinan, pengolahan alat, perhiasan, iklan, pengolahan logam asing berbagai industri pengolahan manufaktur.

Bahan yang diaplikasikan

Kita mesin laser cutting terutama digunakan untuk memotong baja karbon, baja silikon, baja tahan karat, paduan aluminium, paduan titanium, lembaran baja galvanis, papan pengawet, pelat seng aluminium, tembaga dan berbagai jenis pemotongan bahan logam dan sebagainya.

Keuntungan dari Mesin Pemotongan Laser Serat

1) Kualitas balok sangat baik: Diameter fokus lebih kecil dan efisiensi kerja tinggi, kualitas tinggi.

2) Kecepatan potong tinggi: Kecepatan potong lebih dari 45m / mnt

3) Berjalan stabil: Mengadopsi laser serat impor dunia atas, kinerja stabil, bagian-bagian penting dapat mencapai 100.000 jam

4) efisiensi tinggi untuk konversi fotolistrik: dibandingkan dengan mesin pemotong laser CO2, mesin pemotong serat laser memiliki tiga kali efisiensi konversi fotolistrik

5) Biaya rendah & perawatan rendah: Hemat energi dan lindungi lingkungan. Tingkat konversi fotolistrik hingga 25-30%. Konsumsi daya listrik rendah, hanya sekitar 20% -30% dari mesin pemotong laser CO2 tradisional. Transmisi jalur serat tidak perlu mencerminkan lensa, menghemat biaya perawatan

6) Pengoperasian yang mudah: transmisi saluran serat, tidak ada penyesuaian jalur optik

7) Efek optik super fleksibel: Desain ringkas, persyaratan manufaktur mudah fleksibel

8) Dual drive: berbeda dengan mesin tradisional satu drive, daya drive ganda lebih besar, kecepatan lebih cepat dan prosesi tinggi

Parameter Teknis

| model nomor | ACCURL 500W-3015 |

| Kekuatan Laser | 500W |

| Panjang gelombang laser | 1080mm |

| penguat midium | YVO4 |

| lebar garis min | <0.15mm |

| mendorong | drive ganda |

| kecepatan perjalanan maks | 60 m / mnt |

| area kerja maks | 3000 * 1500mm |

Sumbu Z | 120mm |

| ketebalan pemotongan baja karbon | 6mm |

| voltase | 380V / 50HZ |

| Cara pendinginan | Pendingin air |

| Ketepatan lokasi | ≤ ± 0,05mm |

| Format Pendukung | PLT, DXF, BMP, AI |

| Meja kerja maks. beban | 1000KGS |

| Metode Transmisi | Transmisi Sekrup Bola |

| Sistem berbasis tabel | Sistem Servo Motor & Mengemudi Panasonic Impor Jepang |

| Metode Fokus | Mengikuti dan Sesuaikan Fokus Otomatis |

| Metode kontrol | Kontrol Gerakan Offline |

| Kontrol perangkat lunak | Perangkat Lunak Pemotongan Laser Cypcut |