Karakteristik kami mesin laser 1000watt

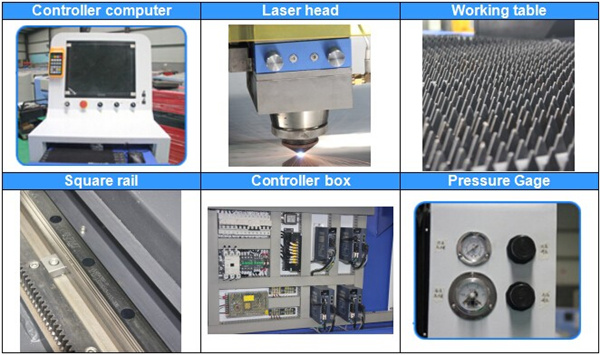

1. Stabilitas dan keandalan sistem jalur cahaya dan sistem kontrol

2. Impor laser serat asli, fungsi tinggi dan stabil, umur lebih dari 100000 jam

3. Kualitas dan efisiensi pemotongan yang lebih tinggi, kecepatan potong hingga 80m / mnt dengan penampilan dan ujung tombak yang indah

4. Peredam, roda gigi dan rak kinerja tinggi Jerman; panduan Jepang dan sekrup bola.

Industri dan bahan yang berlaku dari mesin pemotong laser serat

mesin pemotong laser serat aplikasi:

pemotongan logam, manufaktur saklar listrik, aerospace, mesin makanan, mesin tekstil, mesin teknik, manufaktur lokomotif, mesin pertanian dan kehutanan, pembuatan lift, kendaraan khusus, peralatan rumah tangga, alat, pengolahan, manufaktur IT, mesin minyak, mesin makanan, alat berlian , pengelasan, peralatan las, bahan logam, iklan dekorasi, perawatan permukaan laser dari layanan pemrosesan asing, seperti semua jenis industri pemrosesan mesin.

Kita mesin pemotong laser seratBahan Aplikasi:

Profesional digunakan untuk memotong lembaran logam tipis, dalam berbagai pemotongan lembaran baja karbon 0,5 -3 mm berkualitas tinggi, juga dapat memotong pelat baja tahan karat, pelat paduan aluminium, lembaran galvanis, pelat elektrolit, baja silikon, paduan titanium, pelat seng aluminium dan logam lainnya.

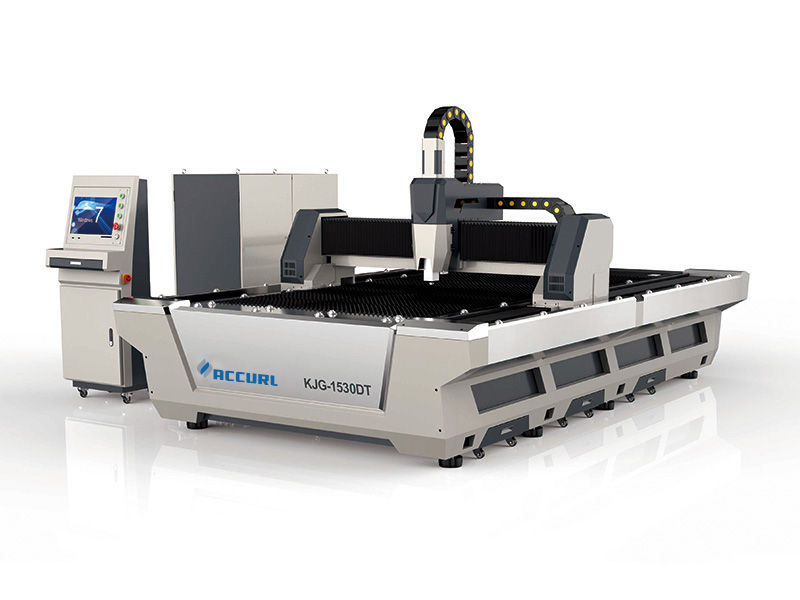

Gambar mesin utama dari Mesin pemotong laser 1kw

Rincian Cepat

Aplikasi: Pemotongan Laser

Kondisi: Baru

Jenis Laser: Serat Laser

Bahan yang Berlaku: Logam

Ketebalan Pemotongan: 0-20mm

Area Pemotongan: 1300 * 2500mm

Kecepatan Pemotongan: 25m / mnt

CNC atau Tidak: Ya

Mode Pendinginan: Pendinginan Air

Perangkat Lunak Kontrol: bechoff (Cypcut)

Format Grafik Yang Didukung: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Sertifikasi: CE, ISO, SGS

Layanan Purna Jual Disediakan: Insinyur tersedia untuk melayani mesin di luar negeri

Model: laser 1000 watt

Bahan pemotong: stainless steel baja karbon dll (mesin laser cutting logam)

Jenis Generator laser serat: Merek terkenal Raycus (Buatan China)

Kepala pemotongan Laser Serat: Lasermech (Dari AS)

Motor & Driver: Motor servo Fuji 1500W buatan Jepang

min. Lebar Garis: ± 0,02mm

Kehidupan kerja modul serat: Lebih dari 100000 jam

Waktu garansi: Seluruh mesin selama 3 tahun (fib

Parameter kami Mesin Pemotongan Laser Fiber

| Model Mesin | 2500 * 1300mm |

| Kekuatan laser | 300W/500W/1000W/3000W |

| Jenis Generator laser serat | Merek terkenal Raycus (Made in China) |

| Panjang gelombang laser | 1064nm |

Laser Beam berkualitas | <0,373mrad |

| Meja kerja | Gigi gergaji |

| Kepala pemotongan Laser serat | Lasermech (Dari AS) |

| Lensa fokus | Lasermech buatan USA |

| Kehidupan kerja modul serat | Lebih dari 100.000 jam |

| Motor & Pengemudi | Motor servo Fuji 1500W buatan Jepang |

| Peredam | 3 set dari Jerman |

| Rel panduan | Merek PMI akurasi tinggi dari Taiwan |

| Sistem pengiriman | Tipe Rak & Pinion Ganda |

| Sistem rak | rak Jerman |

| Sistem rantai | Igus buatan Jerman |

| Pendingin Air | Merek TEYU (S&A), CW6000 |

| Sistem pengaturan | Sistem kontrol laser profesional - Cypcut

|

| Jenis posisi | Titik merah |

| Ketebalan pemotongan | 3mm (baja tahan karat) 6mm (baja karbon) |

| Maks. Idle Running Speed | 1400mm / s |

| Kecepatan memotong | 300mm / s |

| Akurasi posisi | ± 0,05 mm / m |

| Kecepatan Posisi | 20 m / mnt |

| Min. Lebar Garis | ± 0,02mm |

| Konsumsi daya | ≤12KW |

| Membawa beban | 700 kg |

| Voltase | 380V / 50HZ, 3PH |

| Gas Bantu untuk memotong | Oksigen, Nitrogen, Udara |

| Perangkat lunak yang kompatibel | Autocad, Coreldraw, dll |

| Format grafis | Nc |

| Metode kerja | kontrol PC |

| Total peringkat perlindungan daya | IP54 |

| Berat mesin | Sekitar 4000KG |

| Ukuran mesin | 4800*2600*1800mm |

| Waktu garansi | Seluruh mesin selama 3 tahun (modul serat 2 tahun) |

Kontrol kualitas laser 1000watt

Kualitas adalah rasa hormat kami yang tulus yang ditawarkan kepada semua pelanggan kami, dan itu adalah faktor terpenting untuk menjaga hubungan bisnis jangka panjang dengan kami.

Kami selalu lebih memperhatikan kualitas mesin laser cutting. Sistem kontrol kualitas standar dan tim bertanggung jawab untuk memastikan kualitas produk di setiap proses dengan instrumen yang berbeda seperti interferometer laser dan pengukur daya laser.

Dalam proses perakitan mekanis, interferometer laser, kolimator laser, indikator dial, dan pelat marmer digunakan; Dalam proses perakitan laser, meteran daya laser dan mikroskop optik diadopsi.